Introduction and Working Principle of Flue Gas Treatment Equipment

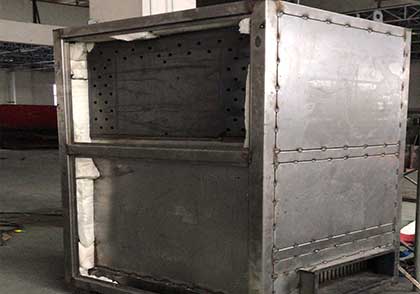

Flue gas treatment equipment (high and low pressure plate type lampblack purification equipment) mainly aims at removing pollutants such as flue gas, oil and gas, solid particles and industrial dust. Especially in the treatment of plastic granulation waste gas, it is perfect. After purification, it can achieve visual smoke-free, purification efficiency can reach 95-99%. It is recommended by the environmental protection department as a flue gas purification device.

After the exhaust gas containing soot particulate matter is inhaled into the high and low pressure plate type end-effluent treatment equipment, some of the larger droplets and oily particles are trapped on the equalizer due to mechanical collision and blockage.

When airflow enters the high-voltage electrostatic field, under the action of high-voltage electric field, the fume gas is ionized, and most of the fumes are degraded and carbonized. Under the action of electric field force and airflow, the movement of the positive and negative plates of the electric field is collected on the plate and flow to the oil collector under the action of gravity

The remaining micron-scale fog plate electric field is degraded into carbon dioxide and water, and the clean air is eventually discharged. At the same time, under the action of the high-pressure generator, the air in the electric field produces ozone, which removes part of the odor in the flue gas. In order to achieve visual smoke-free.

After the exhaust gas containing soot particulate matter is inhaled into the high and low pressure plate type end-effluent treatment equipment, some of the larger droplets and oily particles are trapped on the equalizer due to mechanical collision and blockage.

When airflow enters the high-voltage electrostatic field, under the action of high-voltage electric field, the fume gas is ionized, and most of the fumes are degraded and carbonized. Under the action of electric field force and airflow, the movement of the positive and negative plates of the electric field is collected on the plate and flow to the oil collector under the action of gravity

The remaining micron-scale fog plate electric field is degraded into carbon dioxide and water, and the clean air is eventually discharged. At the same time, under the action of the high-pressure generator, the air in the electric field produces ozone, which removes part of the odor in the flue gas. In order to achieve visual smoke-free.

Applicable industry of flue gas treatment equipment

1. Recycling Granulation Industry

2. Rubber vulcanization industry

3. Treatment of Injection Molding Exhaust Gas

4. Food Industry

5. Printing, dyeing and coating industry

6. Other industries that may produce flue gas and exhaust gas

2. Rubber vulcanization industry

3. Treatment of Injection Molding Exhaust Gas

4. Food Industry

5. Printing, dyeing and coating industry

6. Other industries that may produce flue gas and exhaust gas

Huaxi EP

Huaxi EP

Photoionization Composite Waste Gas Treatment Equipment

Photoionization Composite Waste Gas Treatment Equipment Electrically Heated Catalytic Combustion Equipment

Electrically Heated Catalytic Combustion Equipment UV Photolysis Activated Carbon Integrated Machine

UV Photolysis Activated Carbon Integrated Machine UV photolysis plasma integrator

UV photolysis plasma integrator Washing Tower Waste Gas Treatment Equipment

Washing Tower Waste Gas Treatment Equipment Plasma waste gas treatment equipment

Plasma waste gas treatment equipment Activated carbon adsorption Purification device

Activated carbon adsorption Purification device Photo-Oxygen Catalytic Waste Gas Treatment Equipment

Photo-Oxygen Catalytic Waste Gas Treatment Equipment

Mobile access

Mobile access