Catalytic combustion equipment includes RCO catalytic combustion equipment, activated carbon adsorption and desorption + catalytic combustion equipment, Huaene environmental protection according to the different exhaust gas and site conditions, design different solutions, fully automated equipment, stable operation of the equipment, can reduce operating costs by 30%, do not do one-time sales, to provide you with a comprehensive long-term waste gas treatment solutions.

RCO catalytic combustion technology is widely used in the treatment of organic waste gases from painting, printing, painting, electronics, plastics, plastics, rubber, enameled wire, machinery, motor, chemical industry, instrumentation, automobile, engine, plastics, electrical appliances and other industries. The treatment efficiency is as high as 95%. One investment, housekeeping service, EIA is safe!

Catalytic combustion equipment uses catalysts with noble metals or noble metal oxides (usually platinum, palladium and other noble metal compounds), which can oxidize organic pollutants in exhaust gas to carbon dioxide and water at lower temperatures. It should be noted that the addition of catalyst can not change the original chemical equilibrium, but only improve the speed of chemical reaction, and the nature of catalyst itself does not change before and after the reaction.

Precious metal catalysts are added to the incinerator to catalyze the combustion of organic waste gas and produce non-toxic water and carbon dioxide by oxidation reaction, thus achieving the effect of waste gas treatment.

The catalyst can reduce the ignition temperature required for thermal combustion reaction and save the operation cost of waste gas treatment project. Compared with the traditional exhaust gas purification technology, catalytic combustion exhaust gas purification is more thorough. Coal contact catalytic combustion technology has no open fire in the whole process of reaction, and has higher safety.

RCO catalytic combustion waste gas treatment equipment has a wide range of applications. It can deal with organic waste gas from various industries. The device has simple structure and high efficiency (up to 95%). In terms of energy saving and emission reduction, catalytic combustion technology is more in line with the requirements of environmental protection because of its advantages such as no secondary pollution. It is an exhaust gas purification device pushed by the current national environmental protection department.

Principle of Catalytic Combustion Equipment

Reaction flow chart

After the organic waste gas is filtered by the flame arrester, the main inlet valve and the bypass valve are synchronously reversed, and then enter the heat exchanger. The exhaust gas is heat exchanged by the heat exchanger and heated in the preheater after raising a certain temperature, so that the temperature reaches the catalytic ignition temperature (usually about 250 C).

When the exhaust gas reaches the ignition temperature, it enters the catalytic reaction bed. Under the action of the catalyst, the organic exhaust gas oxidizes to produce harmless water and carbon dioxide, and emits a certain amount of heat. After the reaction, the high temperature gas enters the heat exchanger again. After heat transfer, it is discharged into the atmosphere through the induced draft fan at a lower temperature.

Equipment characteristics

(1) Platinum and palladium plated on honeycomb ceramics as catalysts have a purification efficiency of 97-100%. The equipment has a long life and can be regenerated. The gas flow is smooth and the resistance is small.

(2) Complete safety facilities: fire-proof dust collector, pressure relief hole, over-temperature alarm and other protection facilities.

(3) Preheating for 15-30 minutes with full power. Only the fan power can be consumed when working. When the concentration of exhaust gas is low, automatic intermittent compensation heating is adopted.

(4) The waste heat can be returned to the drying channel for drying, reducing the power consumption in the original drying channel, and can also be used for heat energy reuse in other aspects of the factory.

ACTIVATED CARBON ADSORPTION DESORPTION+CO CATALYTIC COMBUSTION EQUIPMENT (WORKING PRINCIPLE)

Activated carbon adsorption and desorption + catalytic combustion equipment is to adsorb and desorb the exhaust gas first, so that the exhaust gas concentration is appropriate, and then burn in the exhaust gas combustion furnace, so as to reduce the combustion cost.

Organic exhaust gas enters the activated carbon adsorption chamber under the action of induced draft fan. Because activated carbon has many microporous, large specific surface area and strong adsorption capacity, organic exhaust gas is adsorbed in the microporous of activated carbon, and clean air is discharged at this time.

After a period of time, the activated carbon saturates and stops adsorbing. At this time, the organic waste gas is concentrated in the activated carbon adsorption layer. Then we use catalytic combustion technology to desorb and regenerate the saturated activated carbon and put it back into use.

The organic waste gas with high concentration, low air volume and high temperature desorbed by activated carbon filters into a special plate heat exchanger and exchanges energy with the high temperature gas after catalytic reaction. At this time, the temperature of the exhaust gas source is raised for the first time, and then the gas with a certain temperature enters the preheater for the second time.

In the first stage of catalytic reaction, the organic waste gas is partially decomposed at low temperature, and the energy is released. The waste gas source is directly heated to raise the temperature to the optimum temperature of catalytic reaction.

Only after the temperature detection system meets the temperature requirement of the catalytic reaction can it enter the catalytic combustion chamber. The organic waste gas is thoroughly decomposed in the reaction process, and a large amount of heat is released at the same time. The purified gas converts heat energy to cold air through a heat exchanger, and the clean gas is exhausted by an induced draft fan.

Organic matter maintains spontaneous combustion by using the heat released from oxidation combustion. If the concentration of desorbed exhaust gas is high enough and CO does not need electric power heating under normal conditions, it can achieve real energy saving and environmental protection. At the same time, the whole device is safe, reliable and no secondary pollution.

Equipment characteristics

1. The equipment has advanced principle, unique material, stable performance, simple operation, safety and reliability, energy saving and labor saving, no secondary pollution, small occupation area and light weight. The adsorption bed adopts drawer structure, which is convenient for filling and replacement.

2. Compared with granular activated carbon, honeycomb activated carbon, a new type of activated carbon adsorption material, has superior dynamic performance and is very suitable for use in high air volume.

3. Noble metal catalysts supported by honeycomb ceramics are used in the catalytic combustion chamber with low resistance and high activity. When the concentration of organic waste gas is above 2000 ppm, it can maintain spontaneous combustion.

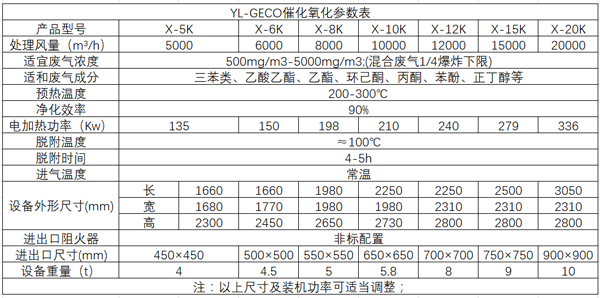

4. Low power consumption. Because of the small resistance of the bed, low-pressure fan can be used. It not only consumes less power but also has low noise. The power of exhaust fan is shown in the attached table.

5. When catalytic combustion occurs, it needs electric heating to start. After the start of catalytic combustion, the combustion heat of organic compounds can be sufficient to sustain the reaction.

Huaxi EP

Huaxi EP

Photoionization Composite Waste Gas Treatment Equipment

Photoionization Composite Waste Gas Treatment Equipment Electrically Heated Catalytic Combustion Equipment

Electrically Heated Catalytic Combustion Equipment UV Photolysis Activated Carbon Integrated Machine

UV Photolysis Activated Carbon Integrated Machine UV photolysis plasma integrator

UV photolysis plasma integrator Flue gas treatment equipment

Flue gas treatment equipment Washing Tower Waste Gas Treatment Equipment

Washing Tower Waste Gas Treatment Equipment Plasma waste gas treatment equipment

Plasma waste gas treatment equipment Activated carbon adsorption Purification device

Activated carbon adsorption Purification device

Mobile access

Mobile access