The plasma is the fourth state of matter after solid, liquid and gaseous state. When the applied voltage reaches the discharge voltage of gas, the gas is broken down, resulting in a mixture of electrons, ions, atoms and free radicals.

Although the electron temperature is very high in the discharge process, the temperature of heavy particles is very low, and the whole system presents a low temperature state, so it is called low temperature plasma.

At present, plasma technology has four main fields, namely dielectric barrier discharge (dual media, single medium), tip discharge (metal, fiber), plate discharge and microwave discharge. In practical applications, combination mode is often used.

Under the action of external electric field, a large number of energetic electrons produced by dielectric discharge bombard exhaust gas molecules, ionizing, dissociating and exciting them, and then trigger a series of complex physical and chemical reactions, which make complex macromolecule pollutants into simple small molecule safety substances, or make toxic and harmful substances into non-toxic, harmless or low-toxic substances, so that pollutants can be reduced. Solution removal.

The average energy produced by electrons after ionization is generally about 10 ev. Proper control of reaction conditions can make chemical reactions which are difficult to achieve or slow in normal conditions become fast. As a high and new technology with strong potential advantages in the field of waste gas treatment, plasma technology has attracted great attention from domestic and foreign academic circles. (Note: Compared with high temperature plasma, low temperature plasma operates at room temperature.)

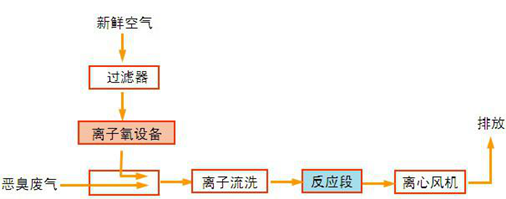

1) Pre-filtration: Effective filtration through air filter to improve the cleanliness of waste gas and the effect of purifying waste gas by ionic oxygen.

2) Oxygenation deodorization: used to further remove the comprehensive odor.

The pre-filtered exhaust gas is introduced into the high concentration ionic oxygen generation area, and mixed with ionic oxygen group, which degrades the odorous pollutants into carbon dioxide, water and other small molecules. The purified air is discharged into the atmosphere through ventilation ducts.

Process 1: Direct bombardment of energetic electrons

Process II: Oxygen atom or ozone oxidation

Process 3: OH radical oxidation

Process IV: Reaction of Molecular Fragments + Oxygen

2. Deodorization characteristics

1) High efficiency of treatment

Ionic oxygen deodorizer can effectively remove hydrogen sulfide (H2S), ammonia (NH3), methyl mercaptan and other specific pollutants, as well as various odors, the effect can reach more than 90%.

2) Safety, reliability and low energy consumption

High-tech ionic oxygen generator and controller, small wind resistance, long service life, minimal power consumption

3) Principle of Pure Physics Method

The oxidation reaction is carried out at room temperature and pressure without secondary pollution.

4) Fully automatic operation of equipment

There is no need for special management, convenient management, very low operating costs, and suitable for intermittent operation. There are two control modes, manual and automatic.

5) Small size, light weight

It covers a small area and is suitable for renovation projects with special conditions such as compact layout and narrow site.

6) Complete equipment, easy to install

2) Wide scope of application, lower capital input than traditional purification equipment

3) Power consumption is lower than other technologies

4) It does not need any preheating time and takes up less space.

5) It can not only reduce the power consumption of plasma, but also control the formation of harmful by-products without liquid excretion.

6) Modular mode is easy to disassemble and handle.

7) In the environment of high temperature 70 C and low temperature - 20 C, the purification zone can operate normally, especially in humid or even saturated air humidity.

8) Long service life of the equipment: The equipment consists of stainless steel, alloy, epoxy resin and other materials. It has strong oxidation resistance and corrosion resistance in acid gas. The service life is more than 10 years.

9) It has the function of dust removal and sterilization, and only needs minimal maintenance.

10) Strong combination of equipment: can be mixed in series and parallel, in the treatment of high concentration odor gas can play an advantage.

|

型號 |

風(fēng)量 |

外形尺寸 |

功率 |

|

YLGY-0.5 |

5000m3/h |

2000×900×1300 |

0.3KW |

|

YLGY-0.8 |

8000m3/h |

2400×1100×1300 |

0.3KW |

|

YLGY-1 |

10000m3/h |

2800×1100×1300 |

0.6KW |

|

YLGY-1.5 |

15000m3/h |

2800×1400×1500 |

0.8KW |

|

YLGY-2 |

20000m3/h |

3600×1400×1500 |

1KW |

|

YLGY-2.5 |

25000m3/h |

3600×1800×1500 |

1.2KW |

|

YLGY-3 |

30000m3/h |

4500×1800×1500 |

1.6KW |

|

YLGY-4 |

40000m3/h |

5300×1800×1500 |

2KW |

|

YLGY-5 |

50000m3/h |

6500×2000×1500 |

2.4KW |

|

YLGY-6 |

60000m3/h |

7600×2000×1500 |

3KW |

|

YLGY-7 |

70000m3/h |

6500×2000×1900 |

3.6KW |

|

YLGY-8 |

80000m3/h |

7000×2000×2000 |

4KW |

|

YLGYL-9 |

90000m3/h |

7500×2000×2100 |

4.8KW |

|

YLGY-10 |

100000m3/h |

8000×2000×2200 |

5KW |

|

YLGY-12 |

120000m3/h |

10000×2000×2200 |

6KW |

Huaxi EP

Huaxi EP

Photoionization Composite Waste Gas Treatment Equipment

Photoionization Composite Waste Gas Treatment Equipment Electrically Heated Catalytic Combustion Equipment

Electrically Heated Catalytic Combustion Equipment UV Photolysis Activated Carbon Integrated Machine

UV Photolysis Activated Carbon Integrated Machine UV photolysis plasma integrator

UV photolysis plasma integrator Flue gas treatment equipment

Flue gas treatment equipment Washing Tower Waste Gas Treatment Equipment

Washing Tower Waste Gas Treatment Equipment Activated carbon adsorption Purification device

Activated carbon adsorption Purification device Photo-Oxygen Catalytic Waste Gas Treatment Equipment

Photo-Oxygen Catalytic Waste Gas Treatment Equipment

Mobile access

Mobile access