Introduction of Electrically Heated RCO Catalytic Combustion Equipment

Electrically heated RCO catalytic combustion equipment (YL-GECO) has very high purification efficiency (up to 97%-99% with easy environmental assessment) in treating mixed organic waste gases such as benzene, alcohols, ketones, esters, phenols, ethers and alkanes. It is suitable for waste gas purification in almost all highly polluting industries, such as painting, printing, painting, plastics, chemical industry, laboratory, food, rubber, etc.

Electrically heated RCO catalytic combustion equipment is a smokeless catalytic oxidation device developed by our company for many years in cooperation with Catalytic Research Institute of Zhejiang University, Precious Metals Research Institute of Kunming, catalyst research and development center of Hangzhou University and famous universities in China.

Electrically Heated RCO Catalytic Combustion Equipment

Working Principle of Electrically Heated RCO Catalytic Combustion Equipment

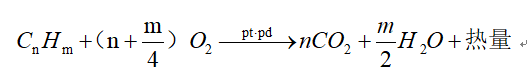

Electrically heated RCO catalytic combustion equipment uses catalysts to oxidize and decompose the combustible components of harmful gases at lower ignition temperature to produce harmless small molecular inorganic substances, so as to achieve the purpose of removing organic waste gases. Under the action of YL-GECO, organic exhaust gas and organic steam are oxidized and decomposed to produce carbon dioxide and water and release a lot of heat energy. The reaction equation is as follows:

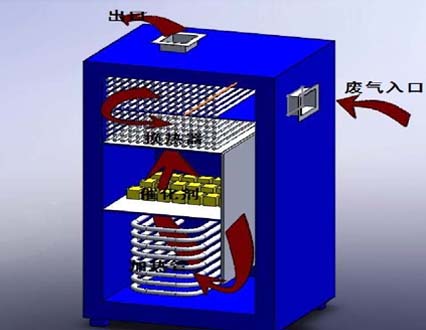

The main structure of electric heating RCO catalytic combustion equipment consists of three parts: core exhaust gas purification device, induced draft fan and control system. Among them, the exhaust gas purification device includes: dust arrester, heat exchanger, preheater and catalytic combustion reaction chamber.

Huaxi EP

Huaxi EP

Photoionization Composite Waste Gas Treatment Equipment

Photoionization Composite Waste Gas Treatment Equipment UV Photolysis Activated Carbon Integrated Machine

UV Photolysis Activated Carbon Integrated Machine UV photolysis plasma integrator

UV photolysis plasma integrator Flue gas treatment equipment

Flue gas treatment equipment Washing Tower Waste Gas Treatment Equipment

Washing Tower Waste Gas Treatment Equipment Plasma waste gas treatment equipment

Plasma waste gas treatment equipment Activated carbon adsorption Purification device

Activated carbon adsorption Purification device Photo-Oxygen Catalytic Waste Gas Treatment Equipment

Photo-Oxygen Catalytic Waste Gas Treatment Equipment

Mobile access

Mobile access