When the mixture gas enters the scrubbing tower from the middle part of the scrubbing tower, because there is liquid product component between the trays, the vaporizing part of the product component gas liquefies at the same time, while the impurities can not be liquefied or solidified, when passing through the tray with liquid component, the liquid product component will be fixed and produce washing effect. The scrubbing tower is designed and manufactured according to this principle.

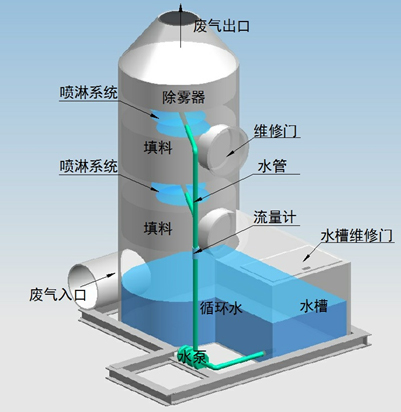

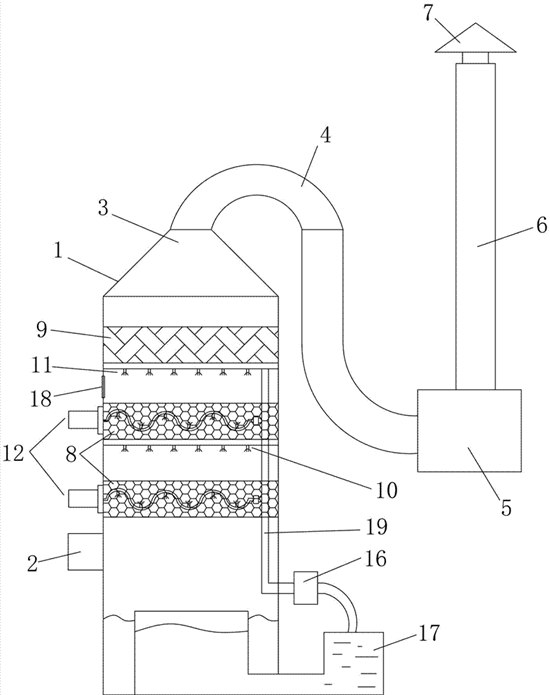

The commonly used washing equipment is packed tower. Chemical absorption liquid sprays downward from the top of the tower, exhaust gas flows upward, odor and absorption liquid are fully contacted and reacted, thus being removed. The ratio of absorbent liquid to waste gas flow (liquid/gas ratio) is generally 1-3 L/m3, the height of packing is generally 2-5 m, and the velocity of empty gas column is generally 0.5-1 m/s. The deodorization effect of the packed tower with good operation can reach more than 90%.

Sodium hydroxide solution containing 1%~10% is commonly used in alkaline absorption solution, which has a remarkable effect on eliminating hydrogen sulfide waste gas. Other substances, such as methyl mercaptan, methyl sulfide, methyl disulfide and low-grade fatty acid, often cause odor in wastewater treatment plant, and the treatment effect is also remarkable.

2) Acidic solution

Acid washing is mainly used to eliminate the odor caused by alkaline gases such as ammonia and trimethylamine. Sulfuric acid (0.5% - 5% solution) is generally used as the washing liquid.

3) Sodium hypochlorite solution

Sodium hypochlorite is usually used with acid-base absorbent solution. For methyl sulfide which is difficult to eliminate by other methods, the control effect of sodium hypochlorite absorbent solution is very good.

When dealing with high concentration odor, the concentration of sodium hypochlorite solution (effective chlorine concentration) is about 500-2000 ppm, while when dealing with low concentration odor, the concentration of sodium hypochlorite solution is about 50-500 ppm. Sodium hypochlorite is the cheapest and most effective oxidant, so it is widely used. Sodium hypochlorite in solution exists in the form of hypochlorite (HOCl):

At pH=l0, only 0.3% of available chlorine exists in HOCl.

At pH=l1 or 12, HOCl almost completely dissociates into useless hypochlorite ions, so pH control is very heavy.

2) Vertical structure is most suitable for economic space installation.

3) Suitable for gaseous and liquid pollution sources;

4) Treatment of a single source of pollution;

5) Suitable for medium and low wind volume;

2) Deodorization devices in waste transfer stations and sewage treatment plants;

3) Exhaust treatment of semiconductor optoelectronic industry;

4) Treatment of leachate from landfill and waste gas from storage tank;

5) Waste gas treatment from incinerators and industrial furnaces.

|

Model |

Size |

Power |

Air volume |

|

|

|

||||

|

YLPL-0.5 |

DN1000*5500 |

1.5 |

5000 |

|

|

YLPL-1 |

DN1400*5500 |

2.2 |

10000 |

|

|

YLPL-2 |

DN2000*6500 |

3.75 |

20000 |

|

|

YLPL-3 |

DN2500*7500 |

5.5 |

30000 |

|

|

YLPL-4 |

DN2800*7500 |

7.5 |

40000 |

|

|

YLPL-5 |

DN3000*7500 |

7.5 |

50000 |

|

|

Model |

Size |

Power |

Air volume |

|

YLPL-6 |

7*3*3 |

11 |

60000 |

|

YLPL-7 |

7.5*3.2*3.4 |

7.5*2 |

70000 |

|

YLPL-8 |

8*3.2*4 |

7.5*2 |

80000 |

|

YLPL-9 |

8*3.5*4 |

11*2 |

90000 |

|

YLPL-10 |

10*3.5*4.5 |

11*2 |

100000 |

Huaxi EP

Huaxi EP

Photoionization Composite Waste Gas Treatment Equipment

Photoionization Composite Waste Gas Treatment Equipment Electrically Heated Catalytic Combustion Equipment

Electrically Heated Catalytic Combustion Equipment UV Photolysis Activated Carbon Integrated Machine

UV Photolysis Activated Carbon Integrated Machine UV photolysis plasma integrator

UV photolysis plasma integrator Flue gas treatment equipment

Flue gas treatment equipment Plasma waste gas treatment equipment

Plasma waste gas treatment equipment Activated carbon adsorption Purification device

Activated carbon adsorption Purification device Photo-Oxygen Catalytic Waste Gas Treatment Equipment

Photo-Oxygen Catalytic Waste Gas Treatment Equipment

Mobile access

Mobile access